SHARE

Custom Telecom manholes thanks to 3D concrete printing - use case Routes et Revêtements SA

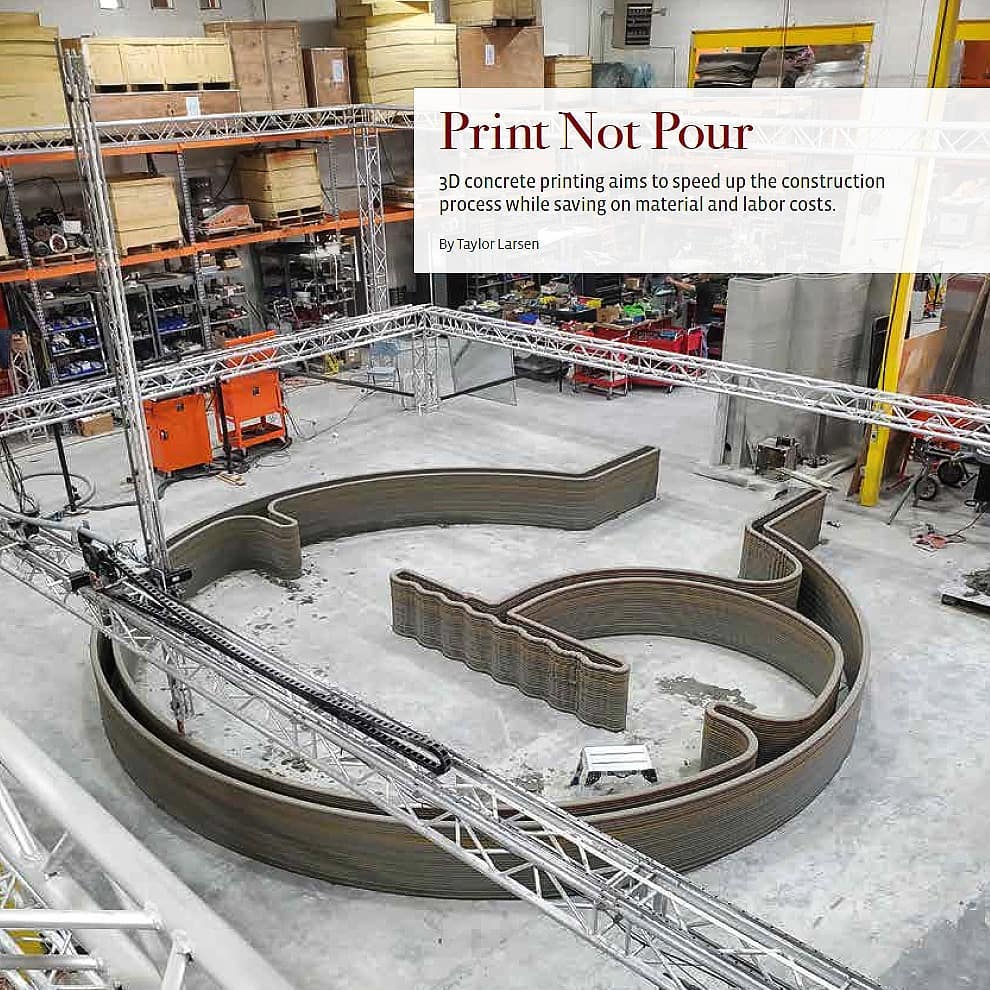

In network construction projects, where several shafts have to be completed per week, the concrete 3D printing process can save time and costs. Due to the flexibility of 3D printing, recesses for cables and a slope can be integrated during production. This means that the method is also suitable for use in more complex installations. It can reduce the intervention from 8 hours to an hour on-site, saving on top of that 25% of concrete. Mobbot, a unique technology: the only 3D concrete print

![Watch this Startup 3D Print Their First Building with a COBOD BOD 2 [In FLORIDA!!]](http://www.concreteprintermagazine.com/uploads/img/500px_075428_maxresdefault-14.jpg.jpg)

![Watch Startup 3D Print Their First Building with a COBOD BOD 2 [In FLORIDA!!]](http://www.concreteprintermagazine.com/uploads/img/500px_012222_00000000000000000000000000000000.jpg.jpg)

Comment Section